Why Are Brazed Diamond Grinding Wheels Becoming the Preferred Choice in Precision Industries?

2025-11-03

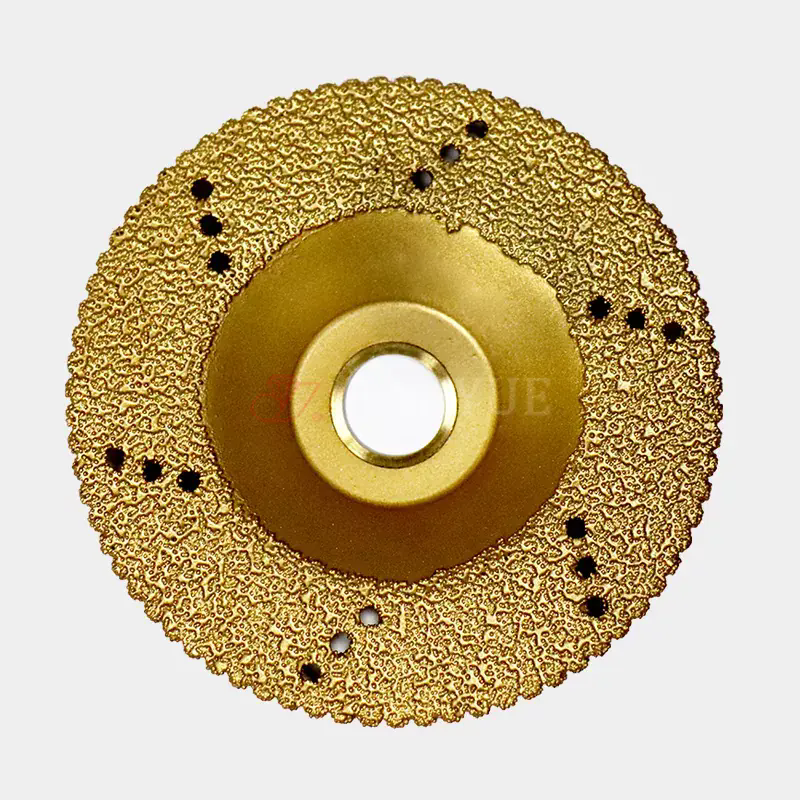

Brazed diamond grinding wheels, also known as vacuum-brazed or metallurgically bonded diamond wheels, represent a next-generation superabrasive tool engineered for high-precision, high-efficiency machining of hard materials.

What is a Brazed Diamond Grinding Wheel?

A brazed diamond grinding wheel is a type of superabrasive tool in which diamond particles are metallurgically bonded to a metal substrate (often via a brazing alloy) rather than embedded in resin, vitrified, or electroplated bonds. Through vacuum brazing or controlled atmosphere brazing, the diamond grit is fixed firmly, exposing a high portion of diamond edges for direct cutting contact.

Such wheels are designed for high rigidity, thermal stability, and consistent abrasive exposure, making them especially suited for machining very hard or brittle materials—such as ceramics, hard carbides, glass, hardened steels, and superalloys.

Core Product Parameters (typical range/values):

| Parameter | Typical Value / Range | Description / Importance |

|---|---|---|

| Diamond grade / quality | 100/120–200/250 mesh, type 2–3 synthetic | Determines hardness, wear rate, cutting sharpness |

| Grit exposure | 70 %–80 % protrusion | Ensures active cutting edges and good chip clearance |

| Bond / filler alloy | Ni-Cr, Cu-Sn, Ag-Cu, Ti-alloy | Metallurgical joining medium that sustains bond strength at high temperature |

| Wheel substrate | Steel or alloy backing | Provides mechanical support and impact resistance |

| Operating speed | Up to 100 m/s or more (depending on design) | High speed enables efficient removal; must avoid overheating |

| Typical life / wear rate | 2–3× that of electroplated wheels (or higher) | Lower replacement frequency in industrial use |

| Cooling / lubrication | Dry, minimal coolant (often no water needed) | Many designs operate dry or with light cooling |

These parameters vary with customization depending on application—some wheels are tuned for maximum sharpness and speed, others for longevity under tough load.

Why Choose Brazed Diamond Grinding Wheels?

Superior Cutting Performance & Efficiency

Because diamond is the hardest known material, brazed diamond wheels offer extremely aggressive cutting. Their sharp edges and stable bonding reduce cutting forces and improve throughput.In comparative tests, brazed wheels have shown up to 30 % higher removal rates on ductile iron compared to conventional tools.

Exceptional Durability & Consistency

The metallurgical bond is far stronger than adhesives or electroplating, resisting grit pull-out even under severe loads or high temperatures.This means more stable grinding performance over the tool’s life and fewer wheel changes.

Thermal Stability & Reduced Wear

The brazed interface tolerates heat more robustly than resin bonds, lowering risk of bond breakdown under heavy heat flux.High temperature resistance helps avoid microcracking and premature wear.

Excellent Chip Clearance & Anti-Clogging

With diamond grits highly exposed, brazed wheels facilitate easy chip ejection and resist clogging—even when machining materials with adhesive chips or resinous binders.

Versatility Across Materials

These wheels are effective on ceramics, glass, hardened metals, composites, silicon carbide, and more.They also reduce vibrational influence, improving surface finish and dimensional control.

Environmental & Cost Benefits

Long service life translates into lower downtime and fewer consumable replacements.Some designs operate dry (no coolant or water), reducing wastewater and environmental impact.

How Are Brazed Diamond Grinding Wheels Used — Practices & Trends?

Application Methods & Best Practices

-

High Speed Grinding: For optimal effect, these wheels are run at higher linear speeds. Care must be taken in cooling to avoid bond degradation.

-

Dressing Strategy: Dressing is less frequent compared to conventional wheels due to stable grit retention.

-

Depth / Feed Control: Conservative initial parameters help protect the bond.

-

Dry or Minimal Coolant: Many wheels are designed for dry use; light air or mist cooling is used if needed.

-

Machine Compatibility: Rigid, vibration-free spindles are ideal to exploit precision grinding with these wheels.

Recent Advances & Research Trends

-

Ultra-Thin Diamond Wheels & Dicing Tools: The brazing method remains a key route for fabricating ultra-thin dicing blades for silicon and ceramics in microelectronics.

-

Micro-Textured & Pulsed Laser Brazing Surfaces: Efforts are underway to texture the diamond bond surface (e.g. via pulsed laser) to enhance chip flow and cooling.

-

Hybrid & Multi-Layer Bonds: Combining brazed diamond layers with conventional support layers to extend tool life is under exploration.

-

Market Growth & Forecasts: The global diamond wheel or edge grinding segment is projected to grow at CAGR ~9.5% through 2033.

Challenges & Mitigations

-

Initial Cost: Brazed wheels are costlier up front than resin or vitrified wheels, but ROI through longevity often justifies it.

-

Limited Rebrazing / Reconditioning: Once grit is worn flat, options to refurbish are limited.

-

Operator Skill: Proper mounting, speed choice, and thermal control are critical to avoid bond failure or thermal damage.

Frequently Asked Questions (FAQ)

What distinguishes a brazed diamond grinding wheel from electroplated or resin-bond wheels?

Brazed wheels use metallurgical bonding to attach diamond grit securely to the substrate, offering stronger adhesion, higher thermal tolerance, and deeper grit exposure. In contrast, electroplated wheels use thin plated layers, and resin-bond wheels use adhesives, which both are more prone to grit loss or matrix degradation under heavy loads.

Can brazed diamond grinding wheels be used without coolant?

Yes — many brazed wheels are designed for dry or minimal coolant operation. Their strong bond and thermal stability permit dry grinding in many circumstances, which reduces fluid usage, simplifies handling, and improves cleanliness. However, in heavy or continuous grinding, light mist or air cooling may still be beneficial to prevent localized overheating.

Outlook & Positioning of JIANYUE

As manufacturing trends pivot toward ultra-precision, miniaturization, and green production, brazed diamond grinding wheels are poised to play a central role. Their combination of high throughput, low maintenance, and environmental friendly profile aligns with smart factories and lean machining. Continued innovation—such as adaptive bond design, laser patterning, and hybrid layer structures—will push performance boundaries further.

The brand JIANYUE is committed to advancing brazed diamond grinding technology through rigorous R&D, tight process control, and customization capabilities to meet high-end demands. JIANYUE’s product line supports tailored grit sizes, bond types, and wheel geometries to match client needs in aerospace, semiconductor, medical, automotive, and tooling sectors. For detailed specifications, testing data, or sample trials, contact us today and let us support your precision manufacturing transformation.