What Makes LED Bulb Mold Critical for High-Quality LED Production?

2025-10-23

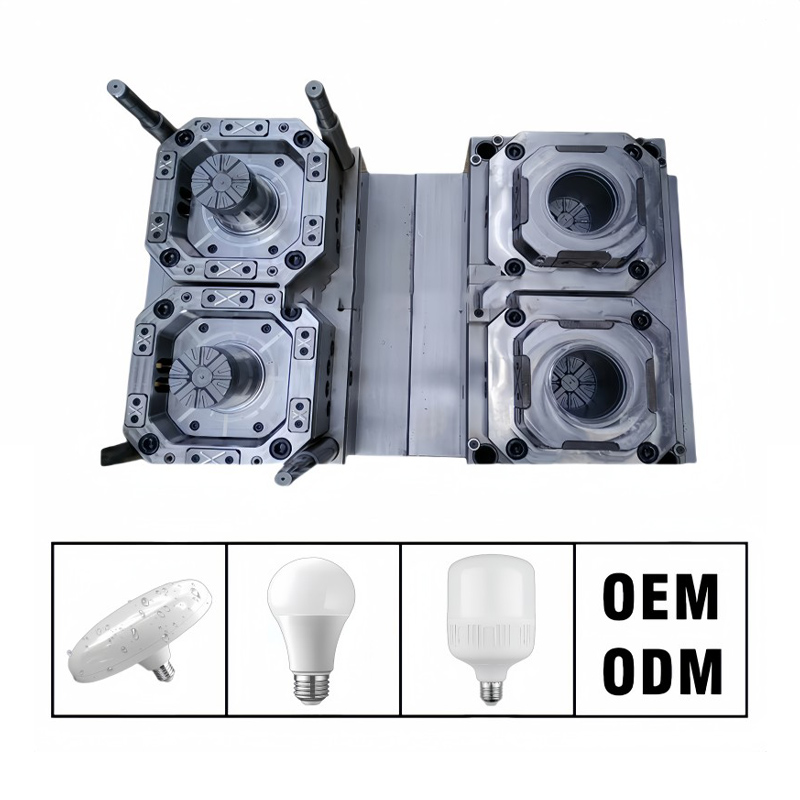

In the fast-evolving lighting industry, LED bulbs have become the cornerstone of energy-efficient illumination. Behind every high-performance LED bulb lies a meticulously engineered LED bulb mold, which ensures precision, durability, and uniformity in production.

LED bulb molds are specialized tools designed to shape the plastic or glass components of LED bulbs with exact specifications. Their design directly influences the performance, heat dissipation, optical clarity, and overall lifespan of the final product. By investing in advanced molds, manufacturers can reduce defects, increase production efficiency, and produce bulbs that consistently meet international standards.

Node 1: What Are the Key Features of LED Bulb Molds?

LED bulb molds are not generic tooling; they are precision-engineered devices tailored for LED bulb components, including the bulb cover, base, and internal heat sink housing. The following table highlights the critical technical parameters of high-quality LED bulb molds:

| Feature | Description | Industry Standard | Benefits |

|---|---|---|---|

| Mold Material | High-grade steel (H13 or P20) | ISO 9001 Compliant | Ensures durability and reduces wear over repeated cycles |

| Precision Tolerance | ±0.01mm | International Standard | Guarantees uniform bulb shape and size |

| Cavity Design | Single or multi-cavity | Varies by production scale | Increases production efficiency, supports mass production |

| Cooling System | Integrated water or oil cooling | DIN Standard | Improves cycle time, reduces thermal deformation |

| Surface Finish | Polished or coated (Ni, TiN) | Ra < 0.2μm | Enhances optical clarity and reduces post-processing |

| Life Cycle | 500,000 – 1,000,000 shots | Manufacturer Spec | Ensures long-term cost-efficiency |

| Venting & Ejection | Automatic air vents and ejector pins | Standard Design | Prevents trapped air bubbles and deformation |

| Compatibility | Universal bulb sizes (A, B, G series) | IEC Standards | Flexibility across multiple product lines |

These parameters are critical for manufacturers aiming to produce bulbs with consistent quality, optimal light output, and reliable mechanical stability. By selecting molds with superior materials, precise tolerances, and advanced cooling systems, production teams can ensure minimal downtime and higher yield rates.

Why Are LED Bulb Molds Vital for Manufacturing Efficiency?

High-quality LED bulb molds do more than just shape components—they directly influence manufacturing speed, product consistency, and cost-effectiveness.

-

Enhanced Production Speed: Multi-cavity molds allow the simultaneous production of multiple bulb shells. This reduces cycle time per unit and increases output, critical for meeting large-scale demand in commercial and residential markets.

-

Improved Product Quality: Precision molds ensure that each bulb has uniform dimensions and consistent optical properties. Imperfections in molding, such as warping or uneven thickness, can cause heat dissipation issues and reduce LED lifespan.

-

Reduced Material Waste: Advanced mold designs minimize excess material use, which not only lowers costs but also supports sustainable production practices.

-

Lower Maintenance Costs: Using high-grade steel and robust cooling systems reduces wear and tear, extending mold life. Fewer replacements and downtime directly translate into operational savings.

-

Design Flexibility: Modern molds can accommodate various bulb shapes, sizes, and light-diffusing patterns, enabling manufacturers to diversify product offerings without significant tooling investment.

Understanding why molds are crucial helps manufacturers justify the initial investment in premium tooling, which ultimately leads to a competitive advantage through superior product quality and operational efficiency.

How to Choose the Best LED Bulb Mold for Production?

Selecting an LED bulb mold requires careful consideration of production needs, material compatibility, and long-term business goals. Below are critical guidelines to ensure the right choice:

-

Material Compatibility: The mold must be compatible with the materials used for the bulb shell, whether high-temperature plastics, polycarbonate, or glass composites. Using the wrong mold material can lead to frequent breakdowns or dimensional inaccuracies.

-

Cycle Time Requirements: Evaluate your production volume and determine whether single-cavity or multi-cavity molds are more suitable. High-volume operations benefit from multi-cavity molds to reduce lead times.

-

Cooling System Efficiency: Adequate cooling channels prevent deformation during molding. Advanced designs optimize water or oil circulation, balancing speed and quality.

-

Surface Finish Quality: The mold’s internal finish directly affects the bulb’s optical clarity. Polished or coated molds reduce post-processing and enhance light diffusion uniformity.

-

Maintenance and Longevity: Molds should be easy to clean, maintain, and service. Regular maintenance schedules and robust design minimize unexpected downtime.

-

Customization Capability: Choose molds that allow for easy modification in case of design updates or new bulb models. Flexible molds provide long-term adaptability in dynamic markets.

Common Questions About LED Bulb Molds

Q1: How often should an LED bulb mold be replaced?

A1: The replacement cycle depends on the mold’s material, production volume, and maintenance quality. High-grade steel molds with proper cooling and regular maintenance can last up to 1,000,000 cycles. Signs of wear, such as surface scratches, dimensional changes, or cooling inefficiencies, indicate the need for replacement.

Q2: Can LED bulb molds be used for different bulb types?

A2: Yes, many molds are designed for universal compatibility with multiple standard sizes (A, B, G series). However, some specialized molds may only support specific designs. Using a universal mold reduces tooling costs and supports faster product diversification.

What Are the Future Trends in LED Bulb Mold Technology?

The LED lighting industry continues to innovate, and mold technology evolves to match emerging demands. Some notable trends include:

-

Smart Mold Design: Integration of sensors for real-time monitoring of temperature, pressure, and cycle times. This data-driven approach ensures quality consistency and predictive maintenance.

-

Eco-Friendly Manufacturing: Molds designed to minimize material waste and support recyclable plastics contribute to sustainable production practices.

-

Advanced Coatings: New mold coatings improve surface finish durability, reduce friction, and enhance optical performance.

-

Rapid Prototyping and Modular Molds: Additive manufacturing enables quick prototyping of molds, reducing lead times for new bulb designs. Modular systems allow manufacturers to swap components rather than replace the entire mold.

-

Integration with Automated Production Lines: Modern molds are increasingly compatible with robotic handling and injection molding automation, boosting efficiency and reducing human error.

By staying ahead of these trends, manufacturers can ensure that their LED bulb molds not only meet current production needs but also remain adaptable to future market demands.

High-quality LED bulb molds from Changhua exemplify these advanced features, offering precision, durability, and flexibility to support diverse LED product lines. Their molds are designed to meet international standards, enhance production efficiency, and maintain consistent optical performance. Manufacturers interested in improving output quality and operational efficiency can contact us to explore Changhua’s complete range of LED bulb mold solutions.