How Does a Fiber Optic Gyroscope Enable High-Precision Inertial Navigation?

2025-12-23

Article Abstract

A Fiber Optic Gyroscope (FOG) is a solid-state rotation sensing device widely used in inertial navigation and stabilization systems. Based on the Sagnac effect, it measures angular velocity with exceptional accuracy, long-term stability, and immunity to environmental interference. This article provides a comprehensive overview of Fiber Optic Gyroscopes, focusing on operating principles, technical parameters, system-level functionality, and industry applications. Through structured “how” questions and detailed answers, the content addresses common technical concerns while aligning with search behavior and professional reading habits.

Table of Contents

- How Is a Fiber Optic Gyroscope Defined in Inertial Sensing?

- How Does a Fiber Optic Gyroscope Work Based on the Sagnac Effect?

- How Are Key Technical Parameters Interpreted?

- How Is a Fiber Optic Gyroscope Applied Across Industries?

- How Do Common Questions About Fiber Optic Gyroscopes Get Answered?

- How Will Fiber Optic Gyroscopes Evolve in Future Systems?

- How Does JioptiK Support Advanced Fiber Optic Gyroscope Solutions?

How Is a Fiber Optic Gyroscope Defined in Inertial Sensing?

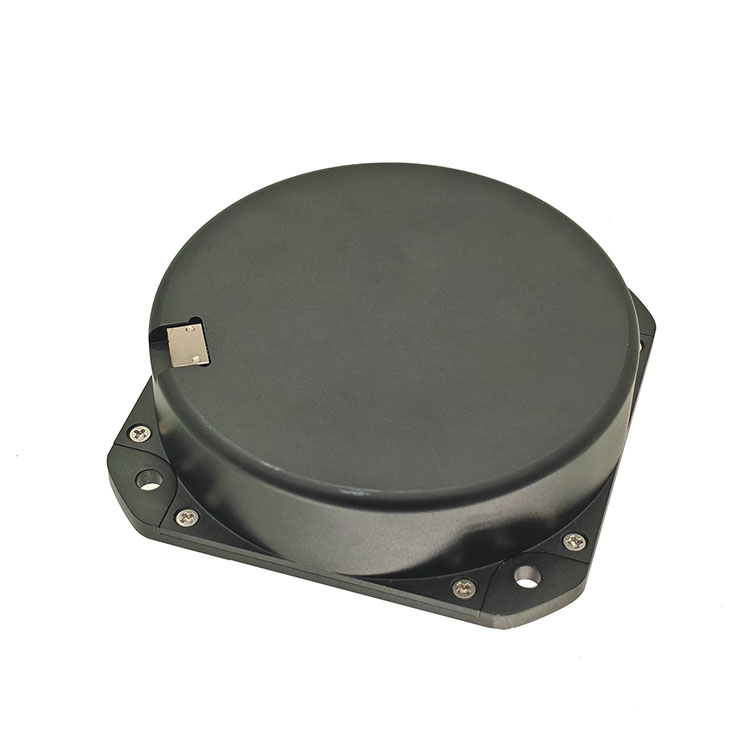

A Fiber Optic Gyroscope is a non-mechanical angular rate sensor that detects rotational motion by measuring the phase difference between two counter-propagating light beams traveling through a fiber optic coil. Unlike traditional spinning-mass gyroscopes, a Fiber Optic Gyroscope contains no moving parts, which significantly enhances reliability, shock resistance, and operational lifespan.

The central focus of this article is to explain how Fiber Optic Gyroscopes function within inertial navigation systems, how performance parameters are evaluated, and how they meet the increasing accuracy and stability requirements of aerospace, marine, defense, and autonomous platforms.

How Does a Fiber Optic Gyroscope Work Based on the Sagnac Effect?

The operating principle of a Fiber Optic Gyroscope relies on the Sagnac effect, a relativistic phenomenon observed when light travels in opposite directions along a rotating closed loop. When the fiber coil rotates, the effective optical path length changes for each beam, creating a measurable phase shift proportional to the angular velocity.

This phase shift is converted into an electrical signal by photodetectors and signal processing electronics. The absence of mechanical inertia allows the Fiber Optic Gyroscope to achieve rapid response times and maintain consistent performance under vibration, acceleration, and temperature variation.

How Are Key Technical Parameters Interpreted?

Evaluating a Fiber Optic Gyroscope requires a clear understanding of its core technical parameters. These parameters define accuracy, stability, and suitability for specific applications.

| Parameter | Description | Typical Range |

|---|---|---|

| Bias Stability | Long-term drift of output when no rotation is applied | 0.001–1 °/h |

| Angle Random Walk | Noise-induced error accumulation over time | 0.0001–0.01 °/√h |

| Scale Factor Linearity | Accuracy of output proportionality to input rotation | < 100 ppm |

| Dynamic Range | Maximum measurable angular rate | ±300–±2000 °/s |

| Operating Temperature | Environmental tolerance range | -40 °C to +85 °C |

Understanding how these parameters interact enables system designers to select an appropriate Fiber Optic Gyroscope for navigation-grade, tactical-grade, or industrial-grade requirements.

How Is a Fiber Optic Gyroscope Applied Across Industries?

Fiber Optic Gyroscopes are widely adopted in applications requiring high precision and reliability. In aerospace, they form the core of inertial navigation systems for aircraft, spacecraft, and launch vehicles. In marine environments, Fiber Optic Gyroscopes support gyrocompasses and dynamic positioning systems where magnetic interference is a concern.

Defense platforms utilize Fiber Optic Gyroscopes for missile guidance, stabilized weapon systems, and unmanned vehicles. In industrial and civil markets, they are increasingly integrated into autonomous vehicles, robotics, and surveying equipment due to their long maintenance-free life and consistent output.

How Do Common Questions About Fiber Optic Gyroscopes Get Answered?

How does a Fiber Optic Gyroscope differ from a MEMS gyroscope?

A Fiber Optic Gyroscope offers significantly lower drift, higher accuracy, and better long-term stability compared to MEMS gyroscopes. While MEMS devices are cost-effective and compact, Fiber Optic Gyroscopes are preferred for mission-critical navigation where precision is paramount.

How is bias drift controlled in a Fiber Optic Gyroscope?

Bias drift is minimized through closed-loop signal processing, high-quality polarization-maintaining fiber, and precise thermal control. Advanced calibration algorithms further compensate for residual environmental effects.

How long can a Fiber Optic Gyroscope operate without recalibration?

Due to the absence of mechanical wear, a Fiber Optic Gyroscope can operate continuously for years with minimal recalibration. This characteristic makes it suitable for long-duration missions and permanently installed systems.

How Will Fiber Optic Gyroscopes Evolve in Future Systems?

Future development of Fiber Optic Gyroscopes is driven by miniaturization, cost optimization, and integration with multi-sensor navigation architectures. Advances in photonic components, digital signal processing, and fiber manufacturing are enabling smaller form factors without sacrificing performance.

As autonomous systems and resilient navigation gain strategic importance, Fiber Optic Gyroscopes are expected to remain a foundational technology, particularly in environments where satellite-based navigation is unreliable or unavailable.

How Does JioptiK Support Advanced Fiber Optic Gyroscope Solutions?

JioptiK focuses on delivering high-reliability Fiber Optic Gyroscope solutions tailored to demanding inertial navigation and stabilization applications. By combining precision optical engineering with rigorous testing standards, JioptiK supports system integrators seeking consistent performance and long-term operational confidence.

For detailed technical specifications, customization options, or application consultation, contact us to discuss how JioptiK Fiber Optic Gyroscope technologies can support current and future navigation system requirements.